In-line Pumps

In-line Pumps – Space-Saving Pumping Solution for Industry (SiamEast Solutions PCL)

In modern industries, the demand for efficient and space-saving pumping systems has become a critical factor for factories and large buildings. One of the most popular solutions is the In-line Pump, from leading brands like Grundfos, designed for easy installation, minimal footprint, and the ability to support complex systems such as cooling, HVAC, and industrial process circulation.

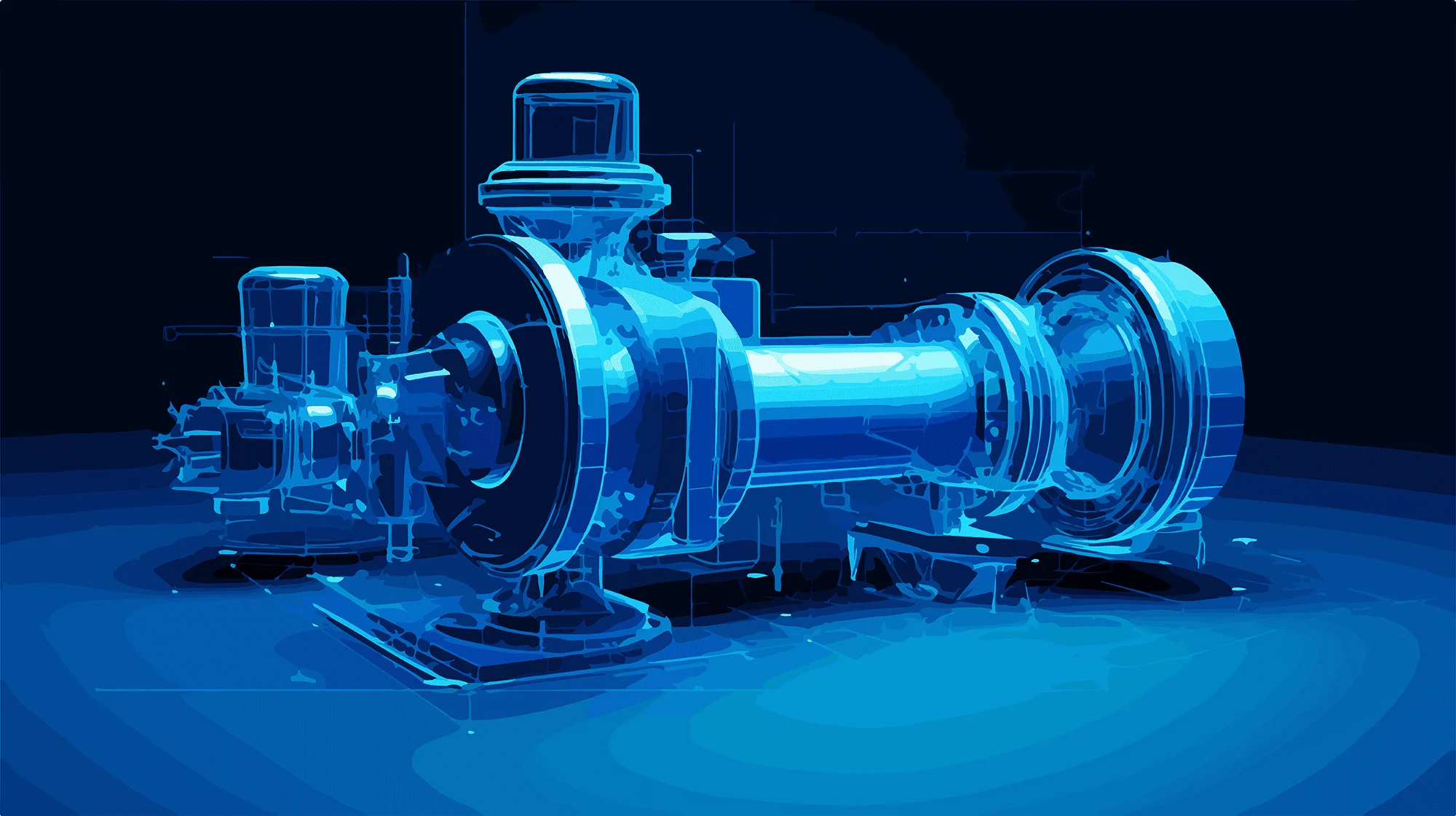

What Are In-line Pumps?

In-line pumps are vertical centrifugal pumps designed so that the suction and discharge pipes are aligned in the same direction. This feature allows for easy integration into existing pipeline systems without requiring major modifications. The result is lower installation costs and reduced maintenance requirements.

Key Advantages of In-line Pumps

- Space-Saving Design

Ideal for factories or buildings with limited space, as they can be installed directly in the pipeline without requiring large pump bases like horizontal pumps. - Easy Maintenance

Grundfos In-line Pumps come with a Back Pull-out Design, enabling removal of the impeller and motor without disconnecting the piping. - Supports Circulation Systems

Perfect for cooling systems, HVAC (Heating, Ventilation & Air Conditioning), and manufacturing processes that require continuous water or coolant circulation. - Energy Efficient

Equipped with high-efficiency motors and compatible with Variable Frequency Drives (VFDs), these pumps help save energy and reduce long-term operating costs.

Industrial Applications

Grundfos in-line pumps are widely used across various industries:

- Chemical Plants → For coolant circulation and temperature control in production processes.

- Food & Beverage Industry → In cooling systems to maintain product quality.

- High-rise Buildings & Shopping Malls → Integrated with HVAC systems to ensure optimal indoor environments.

- Power Plants → For cooling and hot water circulation in power generation processes.

Integration with Piping Systems and Accessories

Since in-line pumps are designed for direct pipeline integration, supporting equipment plays a vital role in ensuring maximum efficiency, including:

- Valves → To control flow and pipeline pressure.

- Expansion Tanks → To prevent overpressure in the system.

- Flow Meters → For monitoring and controlling flow rates in production processes.

- Pipe Fittings → Ensuring smooth and secure pump-to-pipeline connections.

- Strainers → Installed before the pump to filter out debris and protect the impeller.

Why Choose?

- Designed and manufactured according to international standards.

- Wide range of models available—from small-scale systems to large industrial applications.

- Reliable after-sales service and spare parts availability.

- Reduced energy consumption and lower long-term maintenance costs.

Conclusion

Grundfos In-line Pumps are the ideal solution for factories and buildings that require efficient circulation systems, space savings, and ease of maintenance. With direct pipeline integration and compatibility with cooling, HVAC, and industrial production processes, these pumps deliver reliability and efficiency—making them a preferred choice across industries worldwide.